News

Wallivia

Jul. 04, 2022

We wear sunglasses almost every day, from commuting to work to weekend hikes. Have you ever stopped to think about how your favorite sunglasses are made? What are the steps involved in making a pair of sunglasses? What materials are used? Let's dive in and find out how your favorite pair of shades came to be!

Sunglasses are made up of three different parts: the frame, the temples and the lenses. The frame includes several elements such as the nose pads, the nose bridge and part of the hinge. The temples include the other half of the hinge, which is then fixed to the frame using screws, glue or heat. Each part is made individually and then assembled into a finished pair.

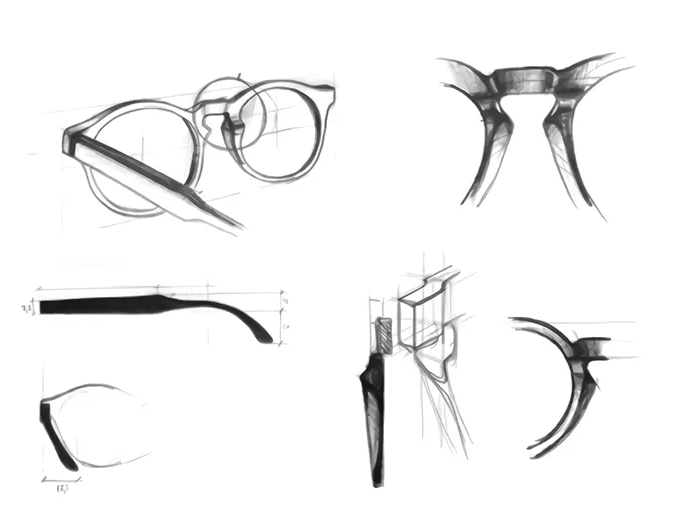

Sunglasses are made starting with the frame, which is the part that holds the lenses in place. First, before production begins, a computer is used to create the size and shape of the desired frame. After creating the design, the frames are made in six steps as follows.

In step 1, create a steel mold or die to match the desired frame shape. The mold has sharp edges, just like a cookie cutter for a blank frame.

In step 2, a plastic material called cellulose acetate is made into a sheet slightly wider than the frame.

In step 3, the blank frames are perforated. The plastic sheets are heated in the oven until they become malleable and then punched with a mold to form the blank frames.

In step 4, excess plastic is removed, the blank frame is removed from the sheet, and the lens portion is removed and scrapped.

In step 5, the lenses are grooved. The frame is held in place by an aluminum fixture and the grooves for the lenses are cut using a router blade.

In step 6, the frame is smoothed using two machines to remove rough edges. The first smoothes the area on the cheeks and the second smoothes the area around the nose.

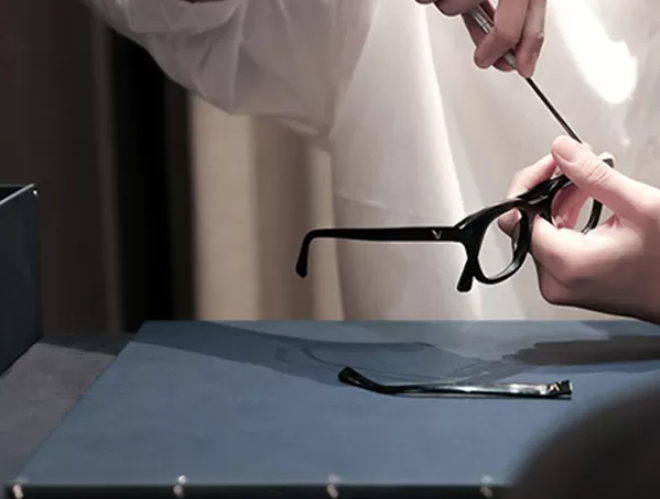

Once the frame is made, the next stage is to make the temples. Sunglass temples are the two arms that go around your ears. These can be a different color or material than the frame, and they often include a brand or logo. See how to make the temples step by step.

Step 1: Melt cellulose acetate into a thin sheet in the oven. This can be the same material as the frame or a complementary material.

Step 2, punch a hole and another steel die to stamp out the blank mirror leg from the sheet.

In step 3, the core is inserted. The blank mirror leg is heated and a steel strip called a core wire is inserted into the center of the softened plastic as reinforcement.

Step 4: Cut the hinge slot. A slot for the hinge is cut in the upper corner of the mirror leg.

Step 5, use heat to melt the hinges to the frame to place and secure the hinges.

Once the temples are secured to the frame, the pair of sunglasses is almost complete! The final step is to make and attach the lenses.

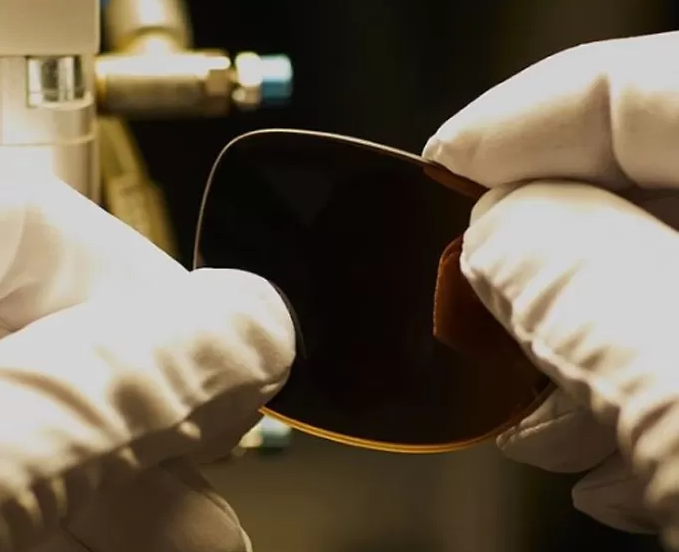

Once the sunglasses frame and temples are made, it's time to make the lenses! Sunglass lenses are made in six simple steps, starting with melted plastic and ending with a fully assembled pair of sunglasses!

Step 1, add the colorant. Colorants are added in two ways, either by adding color to the molten lens material or by chemically coating the finished lenses.

Step 2, pour the molten plastic into the mold to form the general lens shape, such as round, square or cat's eye.

In step 3, a curve is created. The lens is placed into a curve generator that grinds out the back of the lens.

Step 4, trim the lens. The edge grinder is used to trim the lens to the shape of the frame.

In step 5, the lenses are coated with an anti-reflective coating material under vacuum.

In step 6, the finished lens is snapped into the frame recess. The lenses are the most important part of your sunglasses because they protect your eyes from UV rays.

Frames and temples can be made from a variety of materials that are durable, environmentally friendly or exceptionally comfortable.

Plastic is the most popular and cost effective material for sunglass frames.

Metal frames are both durable and lightweight. Metal frames can be made of nickel, stainless steel, aluminum or titanium.

Wooden panels can be laser cut to make non-toxic and usually non-allergenic sunglass frames.

Rubber sunglasses are durable, ideal for children, and more flexible than wood, metal or plastic.

If you want to get your customized glasses, welcome to contact JINGWEI.We offer great design for you.

What is the Meaning of Optical Eyewear?

Oct. 17, 2023How to Get Rid of Scratches on Sunglasses

Sep. 19, 2023How Important is Lens Material for Sunglasses?

Sep. 11, 2023Address

Glasses Industrial Park, Yujiang District, Yingtan City, Jiangxi Province

WhatsApp ID

Copyright ©Yingtan JINGWEI Optical Co., Ltd. All Rights Reserved |

Sitemap

| Technical Support: